working with Brands,Wholesalers,Distributors

20-Year Signage Expert

One-Stop Custom LED Signs For Your Needs

Home » Manufacturing

Our Custom Signage Manufacturing Process

As a professional Custom Signage Factory, Grandview manufactures every sign with extreme caution and efficiency. Using top-tier metal cutting & welding machines, we ensure your brand stands out. Choose a direct custom signage factory to save costs and ensure quality

Skilled Craftsmanship at Our Custom Signage Factory

Grandview is a center of knowledge, expertise and equipment for the development and manufacturing of signage. From metal, plasitc, led light to final signage, we engage ourselves in building supply chain and upgrading our facilities, aiming at bringing both high quality and low price for your custom signages.

100,000+

Annual production capacity of 100,000 pieces signage per year.

80+

Over 80 skilled workers.

20,000

Over 20,000 square meters workshop.

50+

50 units advanced machines for signage

Strict 7-Step Manufacturing Process at Our Custom Signage Factory

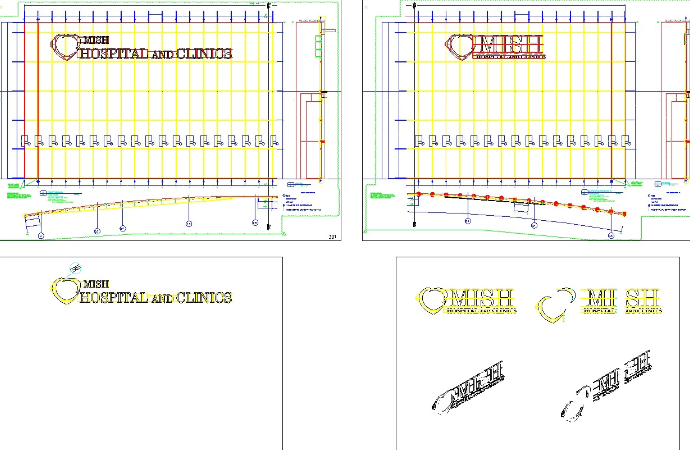

01

PREPARE DRAWINGS FOR CONFIRMATION AND PRODUCTION FILES

Preparing the drawing with size and details for customer confirmed, then make production files, distribute to each department to start produce at the same time

02

Laser Cutting & CNC Engraving for Precision Signs

Cut the stainless steel, aluminum and acrylic etc. According to the production files.

03

METAL BENDING & WELDING SANDING & POLISHING

Preparing the drawing with size and details for customer confirmed, then make production files, distribute to each department to stAccording to the production requirement, bending the metal, welding the face and side/return, sanding the spot to smooth without gap, and polishing the mirror effectart produce at the same time

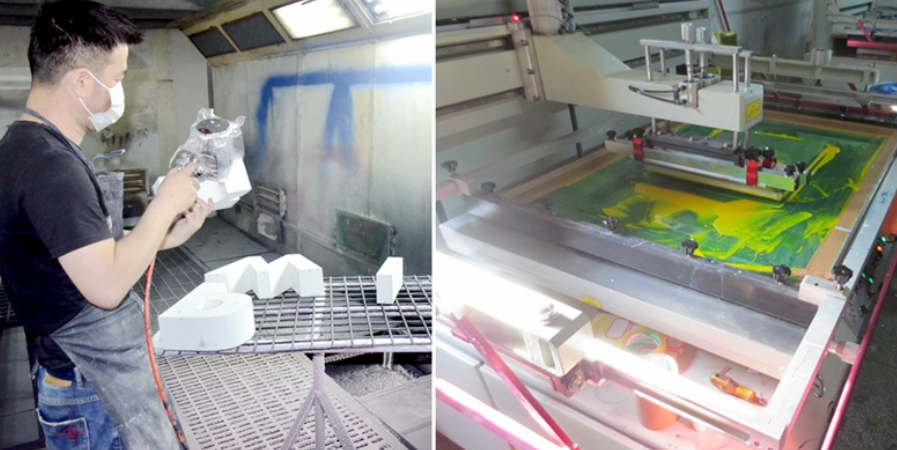

04

PAINTING STICK VINYL FILM ACRYLIC CUTING PICTURES PRINTING

Based on customer’s requirement, stick the correct vinyl film on face, painting carefully and evenly

05

ACRYLIC BENDING THERMOFORMING

Direct printing or Silk screen printing in dust-free workshop, after dry, thermoforming to specific shape with mold

06

LED ASSEMBLY LIGHTING TEST CLEANING QUALITY INSPECTION

Install the led lights according to drawing, make sure have a even brightness, then perform the reliability and stability test. Cleaning after finished, complete inspecation of finished product

07

TAKE PHOTOS PACKING

Final examing all parts including screws, transformer etc. and take photos for archive. Good package avoid any possible damage during the delivery

Quality Control

Grandview makes every sign with extreme caution and efficiency.

Using top of the metal cutting & welding machine and eco-friendly paiting machine, we make every step fast, accurate and countable.

Enjoy the journey of a signage here in Grandview.

Everything for Your signage

Grandview is a center of knowledge, expertise and equipment for the development and manufacturing of signage. From metal, plasitc, led light to final signage, we engage ourselves in building supply chain and upgrading our facilities, aiming at bringing both high quality and low price for your custom signages.。

Sharp Eyes On Flaws

Grandview has been investing heavily in the most sophisticated machines in order to attain higher quality, while we still keep human inspections to eliminate defective products that machines cannot detect. By carefully checking the sample, examining the color, and weeding out those signs with scratches or flaw, we end the manufacturing process with extreme care and caution.

Top-Tier Component Standards

Quality Management, Ensure The Consistency Of Product And Service,we are thoroughly committed to providing high-quality products and exceptional customer service.

01

LED modules have IP68 and more 110 lm/W efficacy from GE Lighting and Blueview

02

Acrylic Panel, ACP have 30 years guarantee non-yellowing unfading from Lucite and Evonik

03

We use Meanwell LED prower transformer, IP65 standard, completely waterproof, suitable for outdoor.

04

We use UV-resistant paint, it will not fade when used near the sea or near the equator.

View our successful projects from our custom signage factory